Customer Spotlight - Mixing Machines and Metal Art

Florida’s Dick Roberts Harnesses the Power of CNC Machines to Build Steel, Copper and Aluminum Art

|

|

When Dick Roberts discovered Torchmate CNC metal-cutting machines, the hours hunched over aviation snips and the days of laborious repetition with a hand-held blowtorch went out the window.

Roberts is a long-time photographer turned innovative metal artist who is on the leading edge of mixing the labor-saving precision of Computer Numeric Control (CNC) machinery with the imaginative creativity of metal artistry.

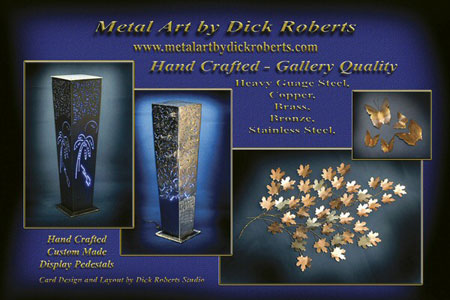

Working out of his Fort Myers, Fla. garage, he’s built complex and intricate steel, copper, aluminum and stainless steel art pieces, often mixing metals into varied, multi-hued pieces that have a rich color composition and distinct texture.

But unlike in years past, when metal artists labored through sweaty afternoons armed with hand torches, aviation snips and grinders, Roberts harnesses technology to create stunning installations in a fraction of the time.

Roberts’ Torchmate 2 — a 4X4 small-shop, robotic, metal-cutting machine— is the primary weapon in his metal art arsenal. The robotic metal-cutting arm can crank out a hundred intricate copper leaves, fabricate multiple metal pedestals, and fashion the outline of a metal art piece that can be then worked by hand into a finished installation — all in a matter of minutes.

“Instead of spending days cutting things out individually, you can make them all at once with a push of the button,” said Roberts.

The introduction of a CNC machine does not rob the artistic process of creativity, said Roberts. It actually accentuates an artist’s ambition and creative drive by relieving him or her of time-consuming rote work.

“Instead of being so repetitive why don’t you spend your time being creative?” asked Roberts. “CNC machines take out the manual, tedious, boring part of the metal art process.”

Roberts finds a lot of his creativity is now channeled into computer design programs and the hands-on manipulation of the CNC-cut metal into a final art piece.

He still uses welders, brushes, snips, grinders and other hand tools, spending his time combining CNC-cut metal pieces, brushing metal into a desired finish, or overlaying metals until the desired artistic effect is created.

The new freedom to spend time dreaming up new art pieces and to experiment with mixed metals has injected a Roberts’ art with a creativity that is prized in the metal art world, where installations are as wildly imaginative as in any art medium.

Roberts, who spent 45 years as a professional photographer and photo studio owner, may seem to be an unlikely candidate to be pushing the limits of technology in metal art. But it his varied experience in the art world, tracking the technological changes that have revolutionized both the field of photography and video, that has helped him keep pace with the changes in metal art.

Roberts made a living in photo darkrooms before digital photography turned his industry on its head. He sees CNC machining as an equivalent advancement in metal art.

“It is just a much higher tech and better way to create metal art,” said Roberts.

From Artist to Teacher

Since purchasing his first Torchmate machine in 2007, Roberts has received a mostly self-taught crash course in CNC machining — and today he is passing on that knowledge to a new crop of metal artists.

“When I first bought my machine I set it up and I tried to read the manual, but I couldn’t understand a thing. I might as well have been reading Chinese,” said Roberts.

Unlike a metal machine shop employee or a fabricator, Roberts had little background in metal-working technology when his Torchmate machine was delivered to his doorstep. As he began researching, experimenting and learning the capabilities of the machine, Roberts realized he was accumulating valuable knowledge that would help the parade of metal artists that would come behind him.

As his metal art career took off, and his work was featured on his website, he began receiving a flood of emails asking how he used CNC machines in his metal art. So he used his videography skills to produce a series of instructional videos about CNC machine use. In a three-part series, Roberts explains the origins of metal art, how to set up a CNC machine, and how to do design work in CAD computer programs.

Today, those videos have drawn an international audience. Roberts sells them through his websites to clients in Australia, Europe, Canada and across the U.S.

The interest is fueled by a growing interest in metal art and the newly affordable CNC offerings like Torchmate’s small shop 2X2 and 4X4 machines. Torchmate’s 2X2 is offered at under $3,000, a price that was unheard of in the CNC field until the 2X2 went into production.

And a lot of Roberts’ knowledge of CNC machining comes from Torchmate’s industry-leading technical support, which is guaranteed for the lifetime of each Torchmate machine.

Roberts’ remarkable success melding metal art with new technology is paying off for him, and the many metal artists that are learning to incorporate CNC machines into their art by buying his instructional videos. Formerly two-day art projects can be cut to 20 minutes, said Roberts.

For metal artists leery of taking the step into CNC machine use, Roberts says the machines are just the latest evolution in an ancient art that has relentlessly progressed from an era of hammers and fire to torches and grinders.

“CNC machines are just the next step up from the technology they are already using,” said Roberts.

To learn more about Dick Roberts’ metal art or his instructional videos, go to: http://www.metalartbydickroberts.com. For more information on the industry-leading small shop CNC machines offered by Torchmate, go to: torchmate.com. |