|

HCI Converting Equipment Co., Ltd.

E-Newsletter

|

Dear Vauled Customer ,

Welcome to the HCI E-Newsletter, bringing you the latest news, technology and events relevant to flexible package industry. HCI provides equipment and technical solutions of all kind of lamination, slitting/rewinding and pouch making processes, please contact HCI Sales to find out more.

|

|

The Applications of Micro Perforated / Breathable Pouches and Technologies of Roll-to-Roll Continuous Piercing / Punching Process on Moving Web

|

|

|

|

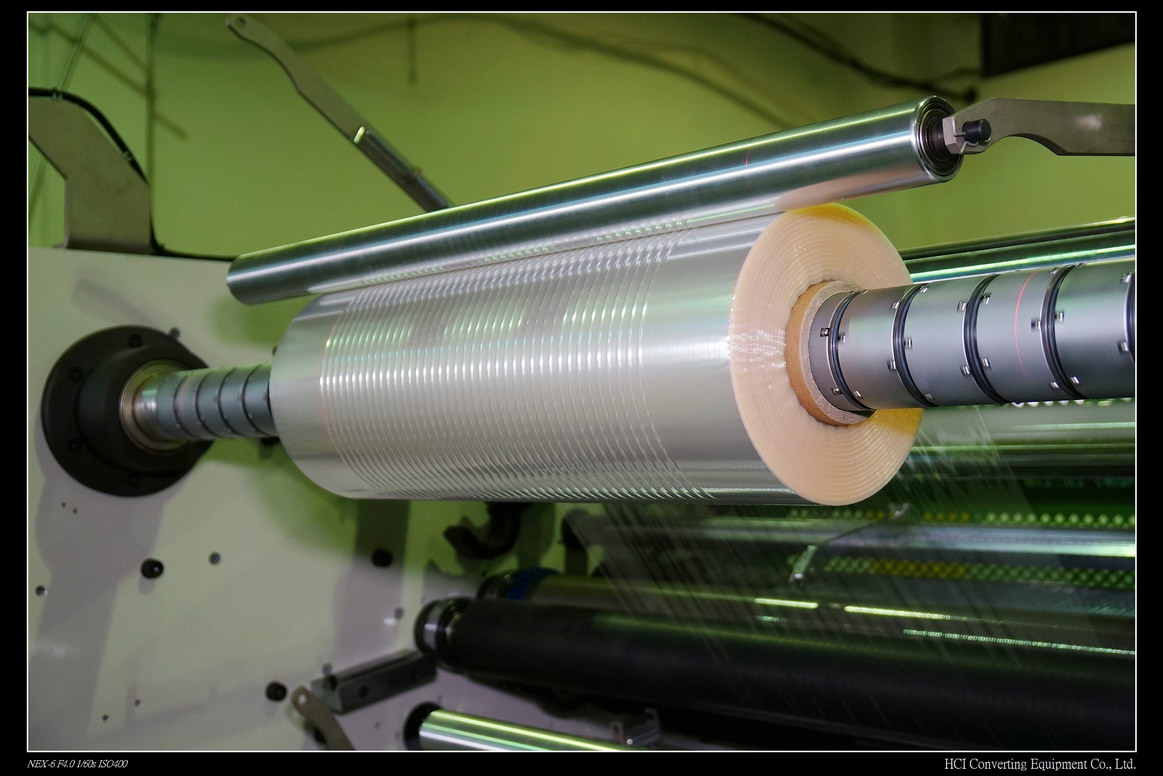

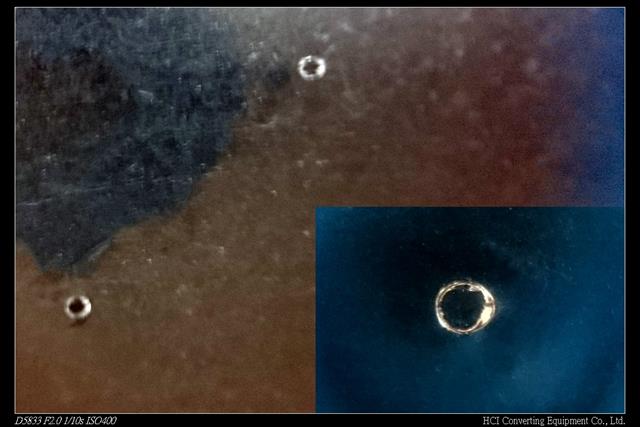

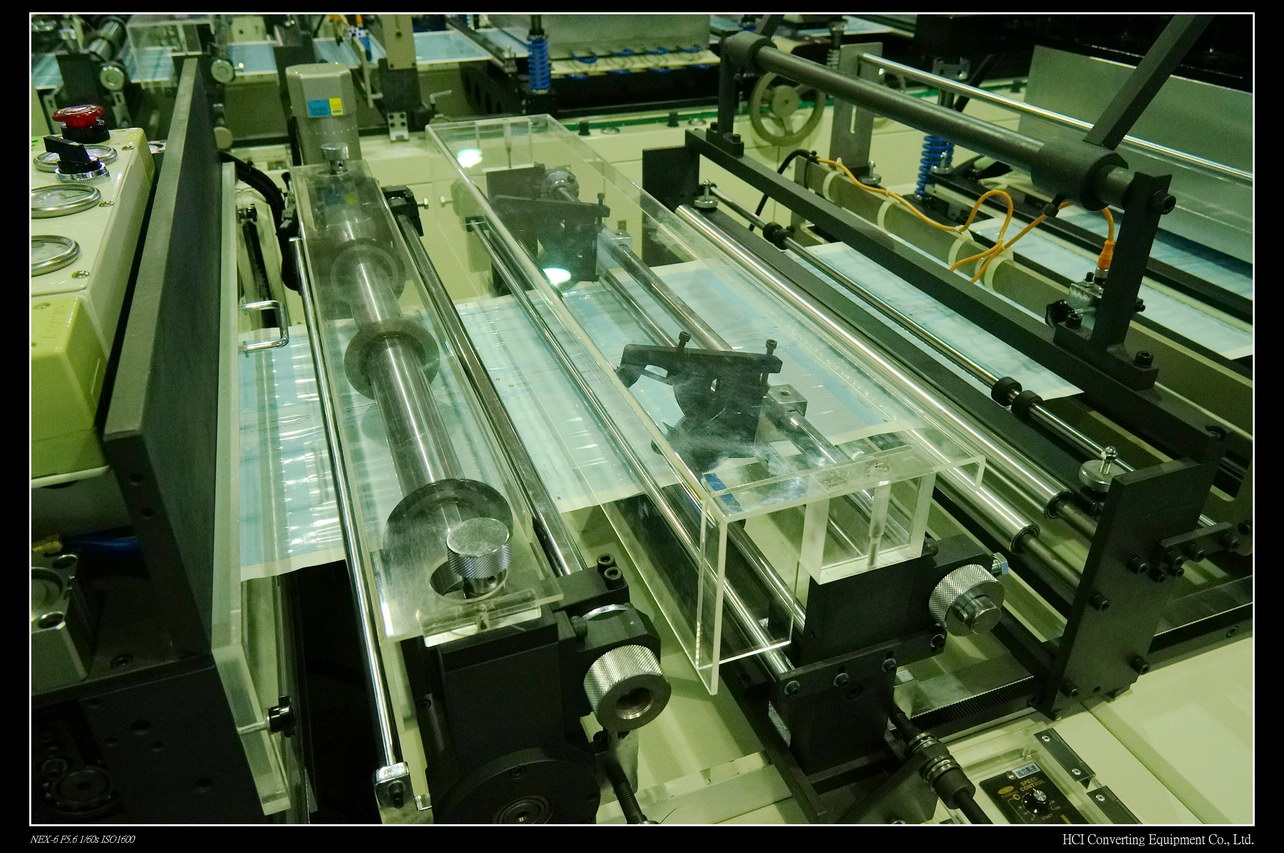

Micro Perforated Pouches / Breathable pouches are mainly used in the packing of fresh vegetables, fruits, flowers and lukewarm foodstuff or any product that needs good aeration and anti-fogging requirement. Prior to the making of micro-perforated pouches, packaging film roll such as PE, BOPP, CPP, PET, and PA have to go through piercing or punching process. Micro vents or holes making can be done by the use of either cold or hot piercing (needled-) roller as well as continuous punching. Cold piercing is the simplest and suitable for use on non-stretchy film but holes created are not round and suffered poor clean cut. Hot piercing can be used on most material but require proper temperature setting to suit different property of material. Holes created are rounder and with cleaner cut. Lastly, continuous punching, a high speed punching on moving webs method is suitable for creating larger holes, lesser in number, that are sparsely distributed over the film surface.

HCI has abundant experience in installing all the above 3 type of vent piercing or holes die cutting process. It can be installed on HCI slitter and rewinding machine to perform roll to roll continuous holes piercing or punching process.

|

|

|

|

|

|

For continuous punching on moving web, HCI uses European branded equipment, capable of punching holes’ diameter of 2mm to 50mm according to customer’s requirement. The smallest side to side pitch between punched holes is 30mm while the back and forth pitch between holes is programmable. Die cutting speed is about 20 strokes per second. Actual test run of continuous punching process fitted on HCI slitter was able to match the slitter line speed of 120m/min. |

HCI Launched Micro Perforation Device for Different Packaging Film

For the hot piercing holes making process, on our customers’ request, HCI has recently successfully incorporated this option on HCI slitters. This was made possible by the vast experience of our team in roll to roll machine design, manufacturing and thermal control. This option is now available on new slitter and rewinding machine as well as for upgrading and customization.

|

|

|

|

|

|

The HCI’s micro perforation process is a standalone device. Hot needle roller is motor driven, capable of auto detect and vary to match the main slitter or rewinding machine working speed. Segment type needle sleeve which can be rearranged to set different hole pitch and hole diameter according to customer’s requirement.

It also equipped with a well-insulated temperature control box offering stable temperature to the needle roller both internally and externally via the multiple thermal sensors and PID thermal controller installed. User friendly PLC HMI touch screen offer operators the option of setting and adjust RPM of needle roller, preheat setting, anvil roller height, working recipe and etc. This HCI’s micro perforation making device can be installed on all HCI slitter and it is capable of achieving holes making or vent piercing line speed of up to 120m/min. To explore more and improve your process productivity, HCI is able to provide all round technical support for both hot piercing and continuous die cutting vents/ holes making device to meet your requirements. Samples are available, please contact HCI Sales to find out more.

|

|

|

Agent Wanted

|

We hope to find the agent with efficient sales organization in those areas to market HCI machinery cooperatively.

If you are in the field of flexible package or related industry, please feel free to contact us.

|

|

2016

Exhibition Schedule

|

| Mar. 1-3, 2016 |

Vietnam :

Propak

|

| March 8-11, 2016 |

Mexico : PLASTIMAGEN |

| 2016 |

Malaysia : 3P Expo |

| April 25-28, 2016 |

China : Chinaplas |

| Aug. 12-16, 2016 |

Taiwan : Taipeiplas |

| Oct. 19-26, 2016 |

Germany : K 2016 |

|

|

Contact Us

|

Website:

www.hci.cc

Email:

info@hci-tw.com.tw

Tel: 886-4-23590632

Fax: 886-4-23590710

Address: 26, 7th Road, Taichung Industrial Park Taichung Taiwan

|

| Join Our Mailing List |

|

| find HCI on facebook |

|

|

HCI Launched New Medical Sterilization Pouch / Reel Making Machine with Precise Temp. Control and User Friendly HMI to Increase Production Efficiency Substantially

Global demand for medical packaging continues to grow, quality standard expected of the sterile pouches/ reels also set to increase and become more stringent. HCI is aware of this trend and has since collaborated with MNCs to make critical changes to its medical pouch making machine to meet this new standard. More operator oriented features, stable and reliable machine with more precise temperature control are the key. A new “FSC-V” is recently launched, capable of making different type of sterile pouches including heat-seal and self-sealing type sterile pouches, flat and gusset sterile reels.

|

|

HCI’s ‘ FSC-V’ medical sterilization pouch making machine’s sealing mechanism utilizes external drive system which is simple and easy to maintain and up keep. Its main drive is servo motor driven and heat sealing time can be varied according to pouch material type. Sealing temperature does not require adjustment while the machine mechanical speed changed. Material feeding is also servo motor controlled ensuring every pouch size is consistently the same.

Heal seal’s sealing pressure and temperatures are 2 critical parameters for ensuring the quality integrity of sterile pouches. FSC-V sealing embossing device utilizes compact cylinder delivering well balance all round pressure to the top and bottom sealing molds, keeping material deformation within 0.01mm during sealing process, especially suitable for paper and film sealing, delivering stronger seal and neat bond.

|

|

|

|

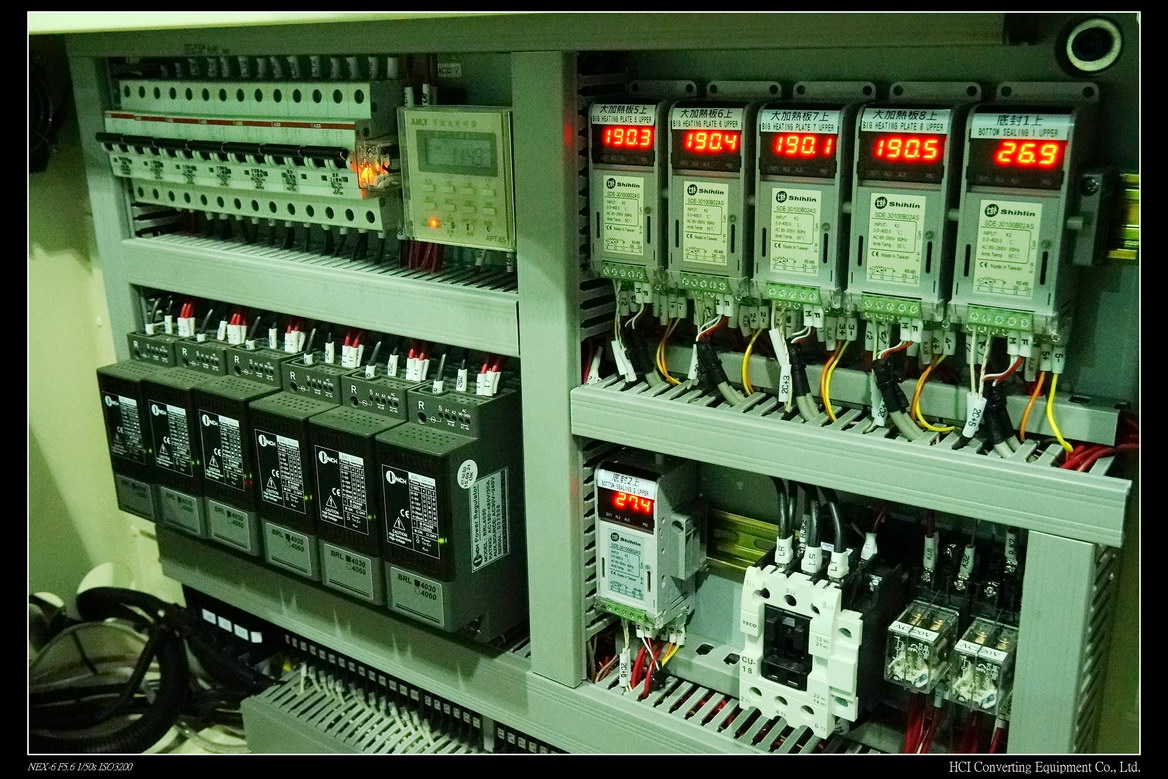

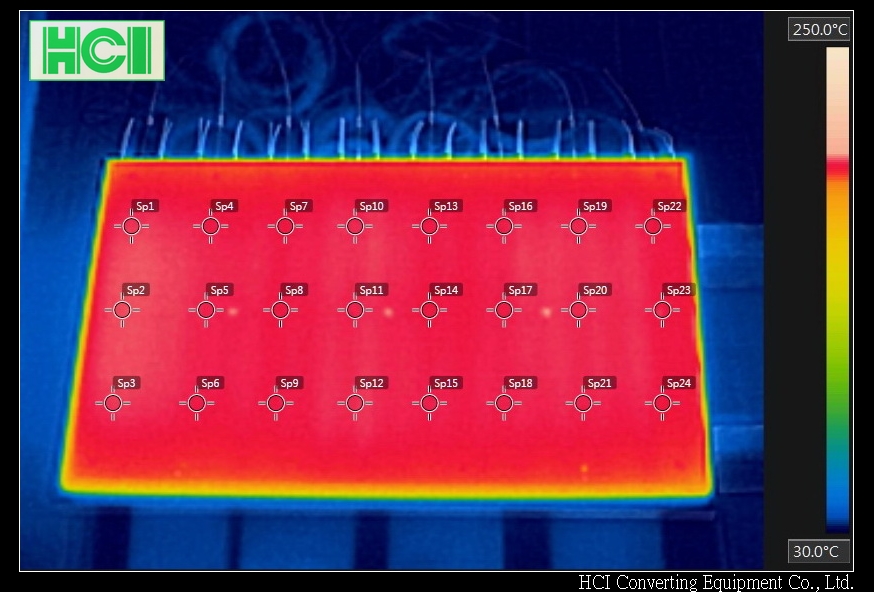

On sealing temperature, FSC-V could be customized to utilize 4 – 8 independent temperature controller according to customer’s requirement. Every set of temperature controller comprises of heaters, thermocouples and PID thermal controller. Each temperature controller will independently controls each zone using HCI’s unique heat distribution technique, temperature on each embossing plate is kept within +/- 2.5 ℃, ensuring zero sealing defect.

|

|

|

|

Other new operator friendly features on FSC-V include improved mold track for easy changing of embossing sealing mold to meet different order. New inline shear knife changing and slitting width changing features are added, without the need to remove knife shaft. HMI touch screen offers easier entering and monitoring of process parameters. The new FSC-V with its new and improved machine design has improved workflow and enhanced safety features, delivering better seal quality, better product and reduces wastage. HCI will continue to bring in new advance technology from the US and Europe providing the most practical packaging solution to our customers. Samples are available; please contact HCI Sales to find out more.

|

|

|

|