HCI Converting Equipment Co., Ltd.

E-Newsletter

|

|

Dear Vauled Customer,

Welcome to the HCI E-Newsletter, bringing you the latest news, technology and events relevant to flexible package industry. HCI provides equipment and technical solutions of all kind of lamination, slitting/rewinding and pouch making processes, please contact to HCI sales find out more.

|

Adjustable Angle Sheeter

HCI Launched Servo Sheeter with adjustable angle cutting device. The cutting slope is from 0 to 15 degrees.

HCI sheeting machine is suitable for all types of plastic, paper, electronics, computer and optical materials, film roll and foil roll. This series can reach high precision and high efficiency of sheeting requirements for users. Since HCI launched this type machine, we already sold out over 100 sets round the world such as Australia, Singapore, Dubai, India, Thailand and Vietnam etc.

Servo drive transmission system provides convenient operation and maintenance, with low noise running, high accuracy of positioning and cutting ensured by numerically controlled DC servomotor, and computerized control reduces errors to a minimum. High quality steel knives ensure clean cutting and a long service life. Heat flattening device, photocell, auto-control, embossing and pouching are available upon request.

In the recent past, HCI received the customized requests of servo sheeting machine from the customer in USA. It’s their first time to establish a factory in Southeast Asia region. As kept the same cost of labor that the capacity has double. In order to reach this requirement, we were the pioneer in the industry that created 2 set FCC machine with mirror structures.

Handing over machines was finished last December. The features of these machines were complete the same, the most special was the structures of design with bilateral symmetry. The placement was opposite direction was a basis period different from that used in past years. One operator can control 2 sets machine on the same aisle. The cutting angle was changeable from 0~15 degrees however he liked. And the cutting length achieved 2.5 meters and feeding speed reached 45 meters per min. Finally, it was valid to help customer make time of back-end process shorter.

Based on over 30 years of manufacturing experience, HCI always provides clients with the most comprehensive technology services. Hound for facing to customization requests, we are going to assist customers catch the business opportunities, reduce producing costing and enhance their market competitiveness.

http://www.hci.cc/Servo-Sheeting-Machine-Video.html

|

|

New Generation Medical Sterilization Pouch/Reel Making Machine

HCI Launched New Medical Sterilization Pouch / Reel Making Machine with Precise Temp.

Global demand for medical packaging continues to grow, quality standard expected of the sterile pouches/ reels also set to increase and become more stringent. HCI is aware of this trend and has since collaborated with MNCs to make critical changes to its medical pouch making machine to meet this new standard. More operator oriented features, stable and reliable machine with more precise temperature control are the key. A new “FSC-V” is recently launched, capable of making different type of sterile pouches including heat-seal and self-sealing type sterile pouches, flat and gusset sterile reels.

|

|

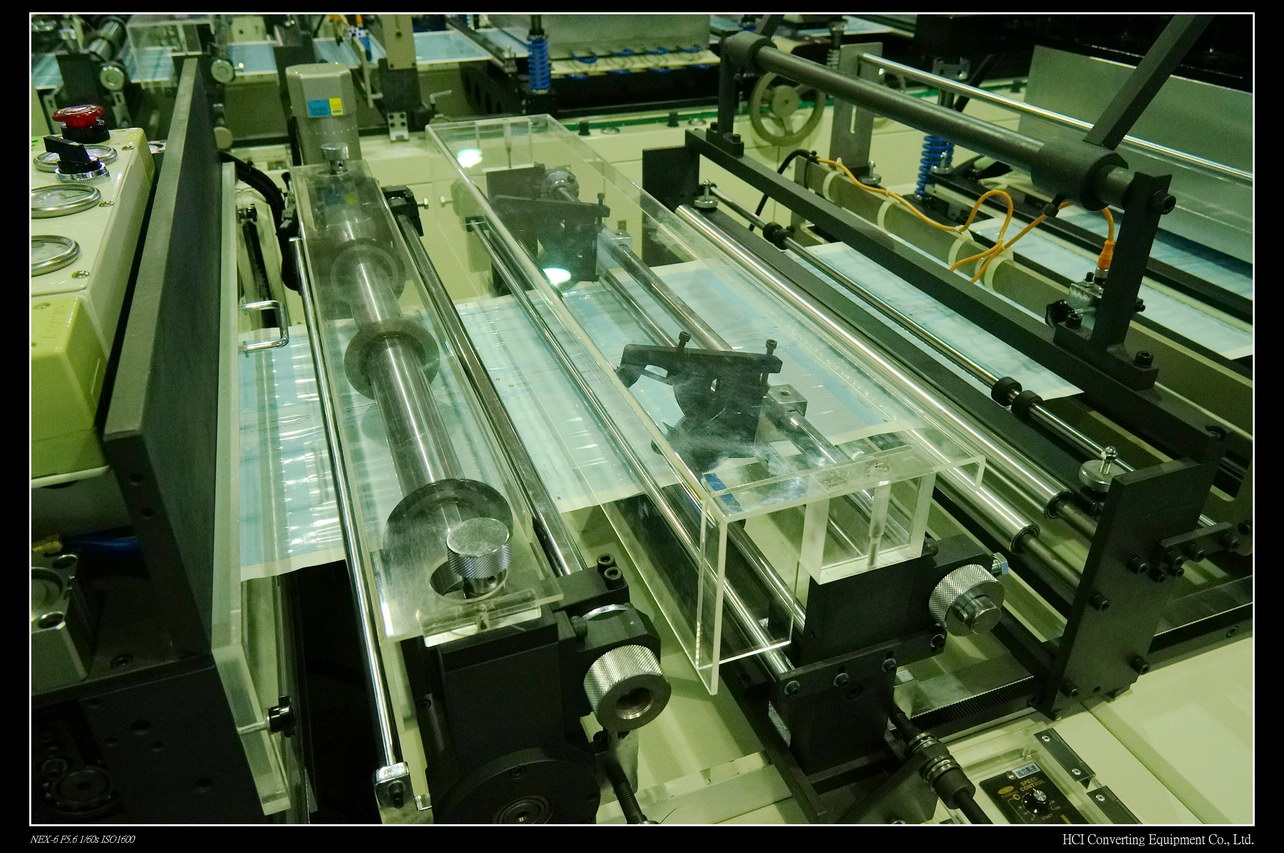

HCI’s ‘ FSC-V’ medical sterilization pouch making machine’s sealing mechanism utilizes external drive system which is simple and easy to maintain and up keep. Its main drive is servo motor driven and heat sealing time can be varied according to pouch material type. Sealing temperature does not require adjustment while the machine mechanical speed changed. Material feeding is also servo motor controlled ensuring every pouch size is consistently the same.

Heal seal’s sealing pressure and temperatures are 2 critical parameters for ensuring the quality integrity of sterile pouches. FSC-V sealing embossing device utilizes compact cylinder delivering well balance all round pressure to the top and bottom sealing molds, keeping material deformation within 0.01mm during sealing process, especially suitable for paper and film sealing, delivering stronger seal and neat bond.

|

|

|

|

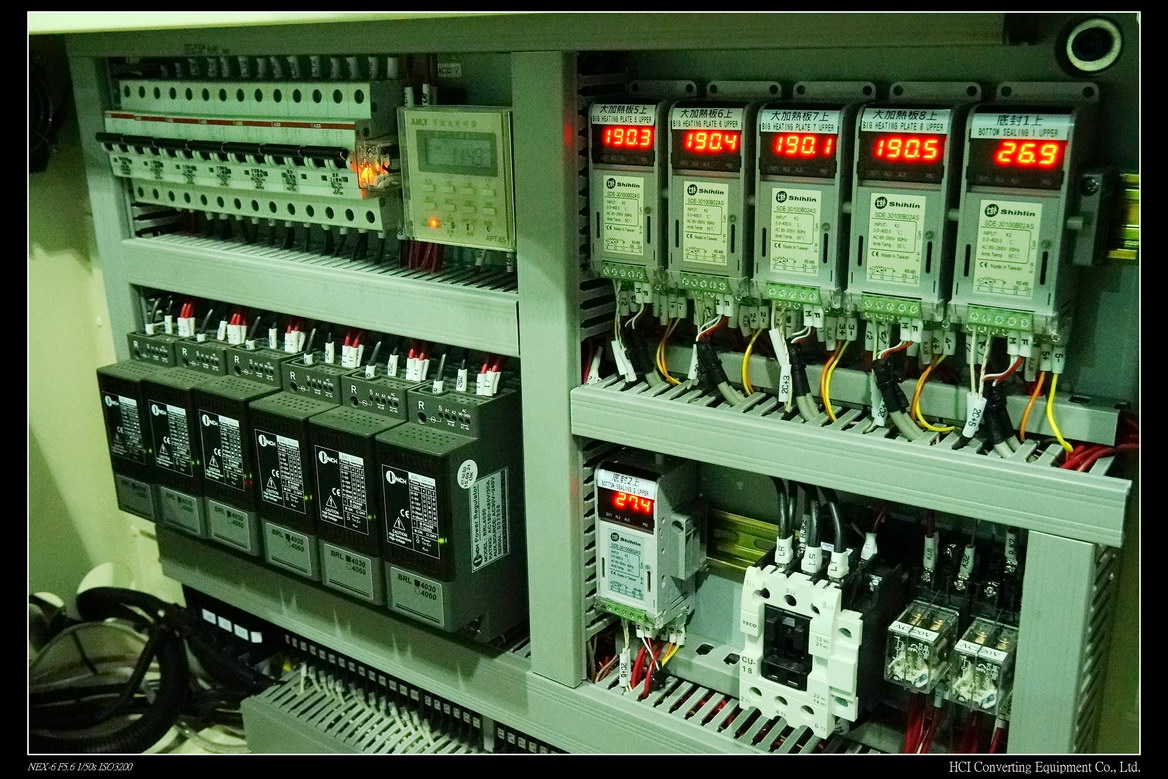

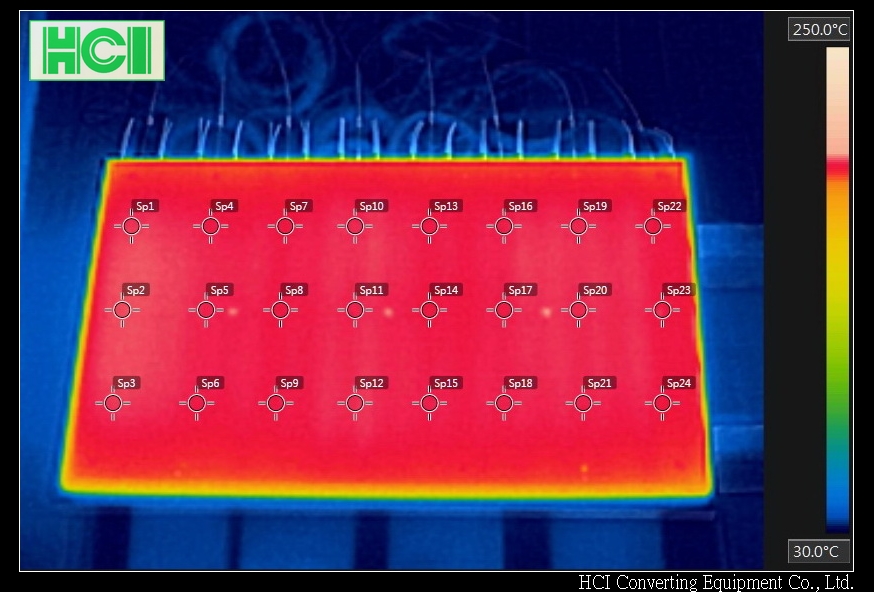

On sealing temperature, FSC-V could be customized to utilize 4 – 8 independent temperature controller according to customer’s requirement. Every set of temperature controller comprises of heaters, thermocouples and PID thermal controller. Each temperature controller will independently controls each zone using HCI’s unique heat distribution technique, temperature on each embossing plate is kept within +/- 2.5 ℃, ensuring zero sealing defect.

|

|

|

|

Other new operator friendly features on FSC-V include improved mold track for easy changing of embossing sealing mold to meet different order. New inline shear knife changing and slitting width changing features are added, without the need to remove knife shaft. HMI touch screen offers easier entering and monitoring of process parameters. The new FSC-V with its new and improved machine design has improved workflow and enhanced safety features, delivering better seal quality, better product and reduces wastage. HCI will continue to bring in new advance technology from the US and Europe providing the most practical packaging solution to our customers. Samples are available; please contact HCI Sales to find out more.

|

|

|

2017/2018

Exhibition Schedule

|

| June 2-4, 2017 |

Kenya :

3P Expo |

| Sep. 13-16, 2017 |

Taiwan : PLASCOM

TAIWAN |

| Nov. 7-10, 2017 |

Mexico:

PLAST IMAGEN |

| Nov. 15-18, 2017 |

Indonesia :

3P |

| Dec. 6-9, 2017 |

Turkey :

Plast Eurasisa ISTANBUL |

| May 29-June 1, 2018 |

Italy :

Plast 2018 |

|

|

Contact Us

|

Website:

www.hci.cc

Email:

info@hci-tw.com.tw

Tel: 886-4-23590632

Fax: 886-4-23590710

Address: 26, 7th Road, Taichung Industrial Park Taichung Taiwan

|

Join Our Mailing List

|

|

| find HCI on facebook |

|

|

Rolling Discharge Device

Time-Saving and Easy-Using. An upgrade option of “Cylindrical Roller Type” discharging shafts for HCI slitting machine.

The traditional cantilevered discharging shaft was designed by iron with electroplated surface. The large OD or wider finished products would be difficult to move in and out from it due to friction via heavy weight. Therefore, operators have to spend more strength and much time to push and pull finished product from this device.

This new type of discharging shaft installs Cylindrical Rollers mechanism on the iron shaft to make the reels moving by “Rolling” instead of “Sliding” friction. The appealing one is operators can finish their work earlier and saving 80% of strength. At the same time, workers can take out materials faster.

Both fixed type and rotary discharge devices can choose the cylindrical roller type of shafts and it also can be add-on HCI existing slitting machine as an easy and useful upgrading. Feel free to contact us for more details.

|

Express Delivery Zone

HCI is taking the advantage of batch production to offer express delivery for some machinery model. You are most welcome to enquire with us about this express delivery service.

| 30 Days (with its existing specification) |

| Model |

Machine Description |

Q’ty |

| FSL-V1300 |

Slitting Machine Deluxe |

1 |

| FSL-TX1300 |

Slitter Rewinder 800mm Rewind OD |

1 |

| FSL-D800-2 |

Small Roll Slitter (for Casher/Thermal Paper) |

1 |

| FSP-400 |

Shrink Label Re-reeling and Doctoring Machine |

1 |

| FSR-N600 |

Rewinding Machine |

1 |

| FPT-600 |

Core Cutting Machine |

1 |

| 50 Days (with limit specification changes) |

| FSL-K1300 |

Slitting Machine Standard |

1 |

| FSL-KA1300 |

Slitter Rewinder Practical |

2 |

| FSL-KT1300B-A1 |

Slitting Machine Integration |

1 |

| FSL-TX1300 |

Slitter Rewinder 800mm Rewind OD |

3 |

| FK-250PVC |

Sleeve Seaming Machine |

1 |

| FSC-201 |

High Speed Cutting Machine |

2 |

| FSC-301PVC |

High Speed Cutting Machine |

1 |

| FSP-250-2 |

Shrink Label Re-reeling and Doctoring Machine |

2 |

|

|

|

|